Pedaldude

Well-known member

As mentioned above, hopefully at least the Pro will have a better OEM accessory battery that can easily be adapted. Or maybe they will change it for 2024 once Ford realizes that owners will be doing more than posing for picnic photos on the beach and driving through mud puddles on test tracks as part of their off-roading.With the big front trunk already having power to it, I'd bet some McGyver will quickly figure out how to use it for a winch and probably a lot of other stuff.

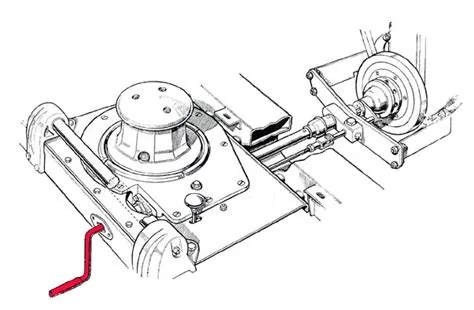

It's a packaging problem, there would be zero issues other than another shaft seal through the case. We're talking 100 year old technology and it's a $200 option on the F250. Weight depends on how it's implemented but if an existing shaft is used it would be negligible. I don't know how much weight is added on the F250, you would have to compare the GVWR and payload stickers between two identical builds, one with Live-Drive and one without....Trying to build on a mechanical PTO to drive motor creates a lot of issues.

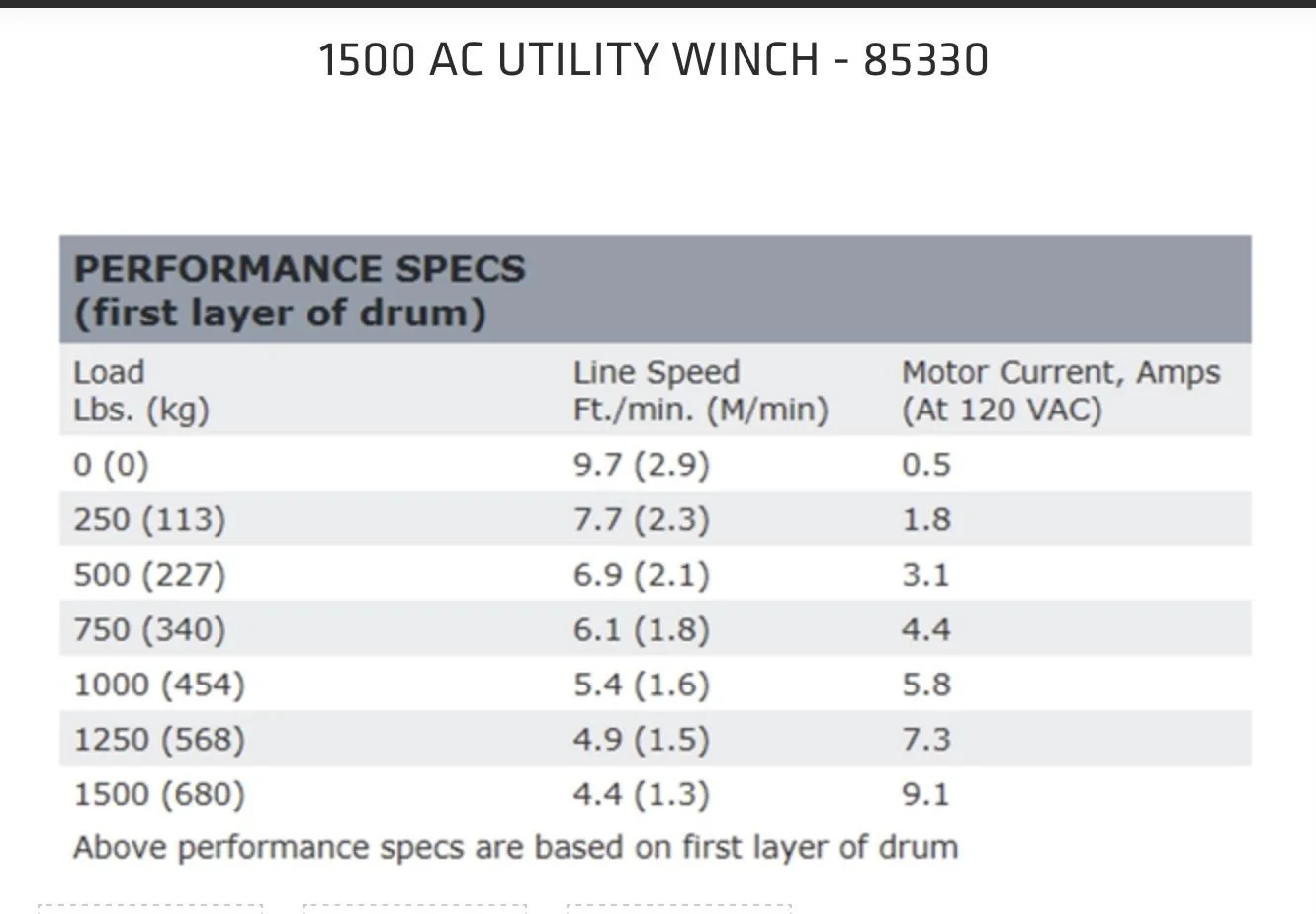

How big does a winch motor need to be?

Sizing on an a winch depends on how you anticipate using it. For recovery, off-road dudes like to run a winch rated 1-2X their vehicles GVWR but if it's just a utility winch to drag around shit that is to heavy to lift or to operate a gin pole, depending on what you are doing, it could be a winch rated for a few hundred pounds.

As far as the Lightning's drive motor, it would definitely be overkill, a 5HP 12V winch motor on a 9,500lb winch might weigh 20lbs with the actual winch components weighing 70-80lbs, a 35GPM PTO driven hydraulic pump will weigh around 50lbs but would power a 40,000lb industrial winch that weighs over a quarter ton. That's why the PTO is still used for work trucks but pretty much only to power hydraulics, as they're cheaper, lighter and harder to kill than the equivalent electric motor. Really, the only current application is plow, dump and bucket or boom truck hydraulics.

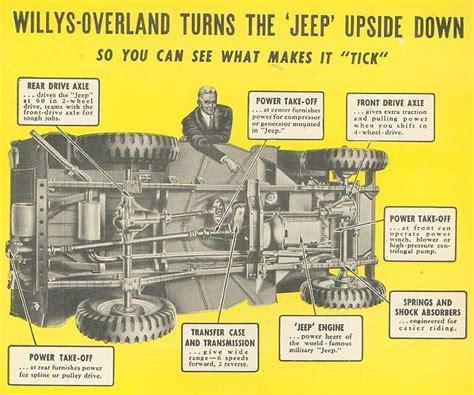

There's really no modern comparison for the light truck segment, since the majority of trucks sold are generally used in the same way as a station wagon or minivan. Back in the day though you could get a Willys Jeep or Land Rover with front and rear PTO shafts, so there is precedent. The only thing is with cheap manufacturing, electric motors that used to be fairly expensive are now plentiful and cheap, so all the accessories that used to be run by small tractors or Jeeps are now less expensive with motors than without. If you wanted a PTO 3-point mounted cement mixer, it will cost $1,200. A very similar cement mixer with the same capacity and a 120V motor will cost $300 because of much higher demand. You can get a generator to run the mixer and be way ahead financially while still being able to use it remotely.

Still, I think that a PTO would be pretty sweet! It would also solve the flat towing problem, since the transaxles would need a neutral. Maybe Jeep will do something with their new EV Wrangler models eventually. Jeep will have less of a packaging problem with minimal front and rear overhang.

Sponsored