Marcelo Zanetti

Well-known member

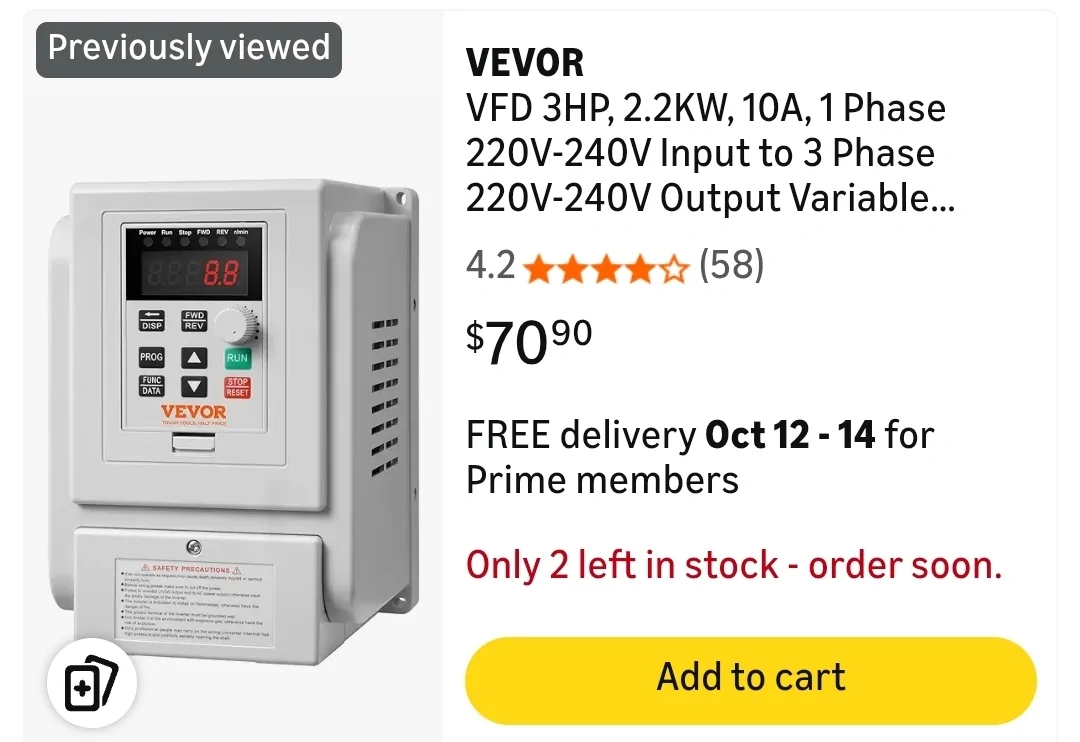

There are single phase to three phase converters, but they are not cheap. You might just bag the three phase grinder and purchase a regular 120 or 240V type.

You can search up here.

https://www.northamericaphaseconver...-converters/pro-line-rotary-phase-converters/

You can search up here.

https://www.northamericaphaseconver...-converters/pro-line-rotary-phase-converters/

Sponsored