Sponsored

Stick to Rotary Shift Knob Conversion w/ 3D Printed Rotary Shifter Holder

ENDianDigital

Active member

I got a chance to create a cut version using the tool @boggle sent me.If you want to hold off a bit, I'm going to try seperating the body with the convoluted tool boggle sent me. Feel free to give it a go now of course, but I do think the sidewall will be much sturdier and locked in once I use that tool. I just haven't had time to work on it yet.

New version uploaded to Thingiverse

BennyTheBeaver

Well-known member

Attempting to print this now. I'm slowing the printing down so it will take a little while to get everything printed (assuming no print issues).I got a chance to create a cut version using the tool @boggle sent me.

New version uploaded to Thingiverse

Mcbutter

New member

- First Name

- Josh

- Joined

- Apr 14, 2022

- Threads

- 0

- Messages

- 3

- Reaction score

- 1

- Location

- Williamsburg, Va

- Vehicles

- 2004 F250

- Occupation

- System Protection Technician

Looking back at your previous posts it looked like you had used ASA filament? If you did and you still have it available I'm interested in it.I've got this laying around if anyone is interested.

sstevetx

Well-known member

- First Name

- Steve

- Joined

- Sep 3, 2023

- Threads

- 3

- Messages

- 275

- Reaction score

- 473

- Location

- Dallas, TX

- Vehicles

- 2022 Lariat ER w/Max Tow - Atlas Blue

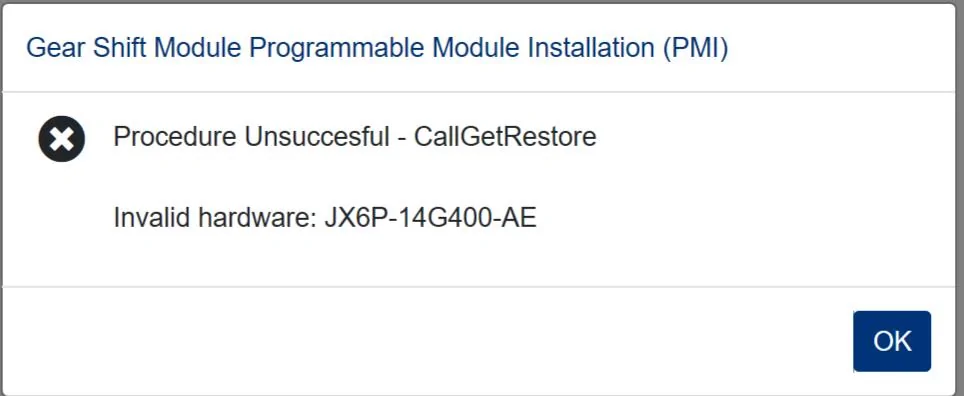

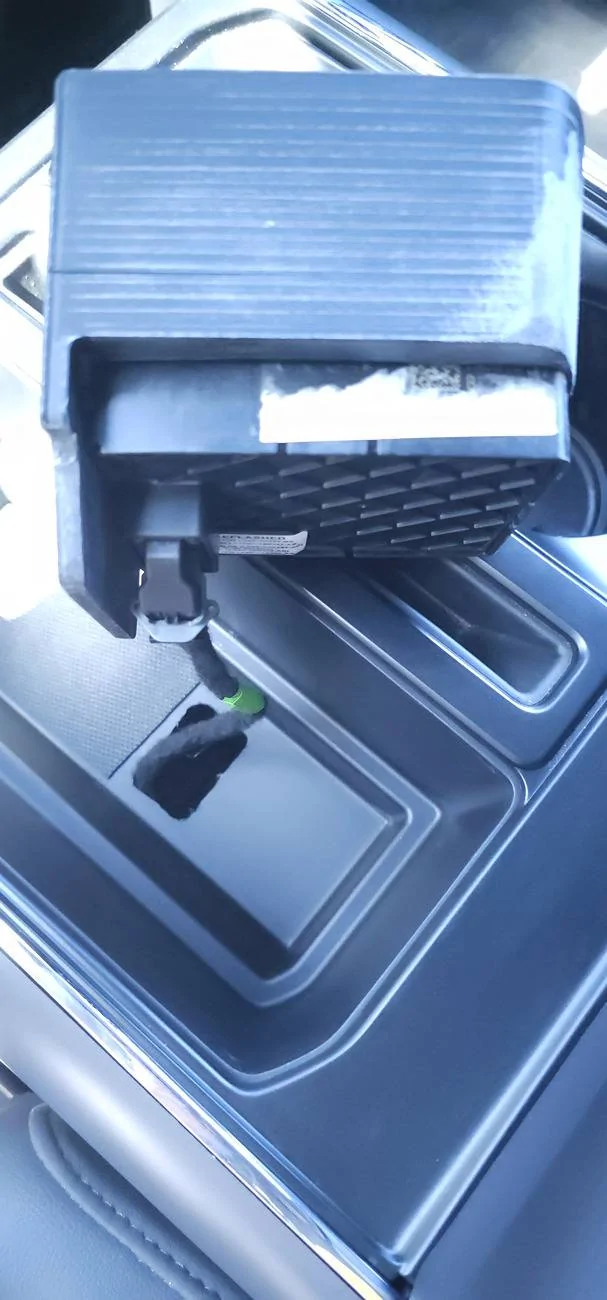

I was doing some FDRS updates today and I have the rubberized Bronco sport rotary shifter (LX6P-7P155-LE) installed. I checked and there were no DTCs listed with the GSM and it showed green in FDRS. I did a read on the GSM configuration, and it came back with the part number I mentioned earlier.

I decided to attempt a PMI on the GSM since I had FDRS open. I tried it stating I had the original module and then again stating I did not have the original module and both attempts failed. It's not surprising, but figured I would let others know who were curious. I did do a VIN Write operation in FDRS which was successful and tried the PMI both ways again and both failed.

I decided to attempt a PMI on the GSM since I had FDRS open. I tried it stating I had the original module and then again stating I did not have the original module and both attempts failed. It's not surprising, but figured I would let others know who were curious. I did do a VIN Write operation in FDRS which was successful and tried the PMI both ways again and both failed.

Last edited:

Sponsored

boggle

Well-known member

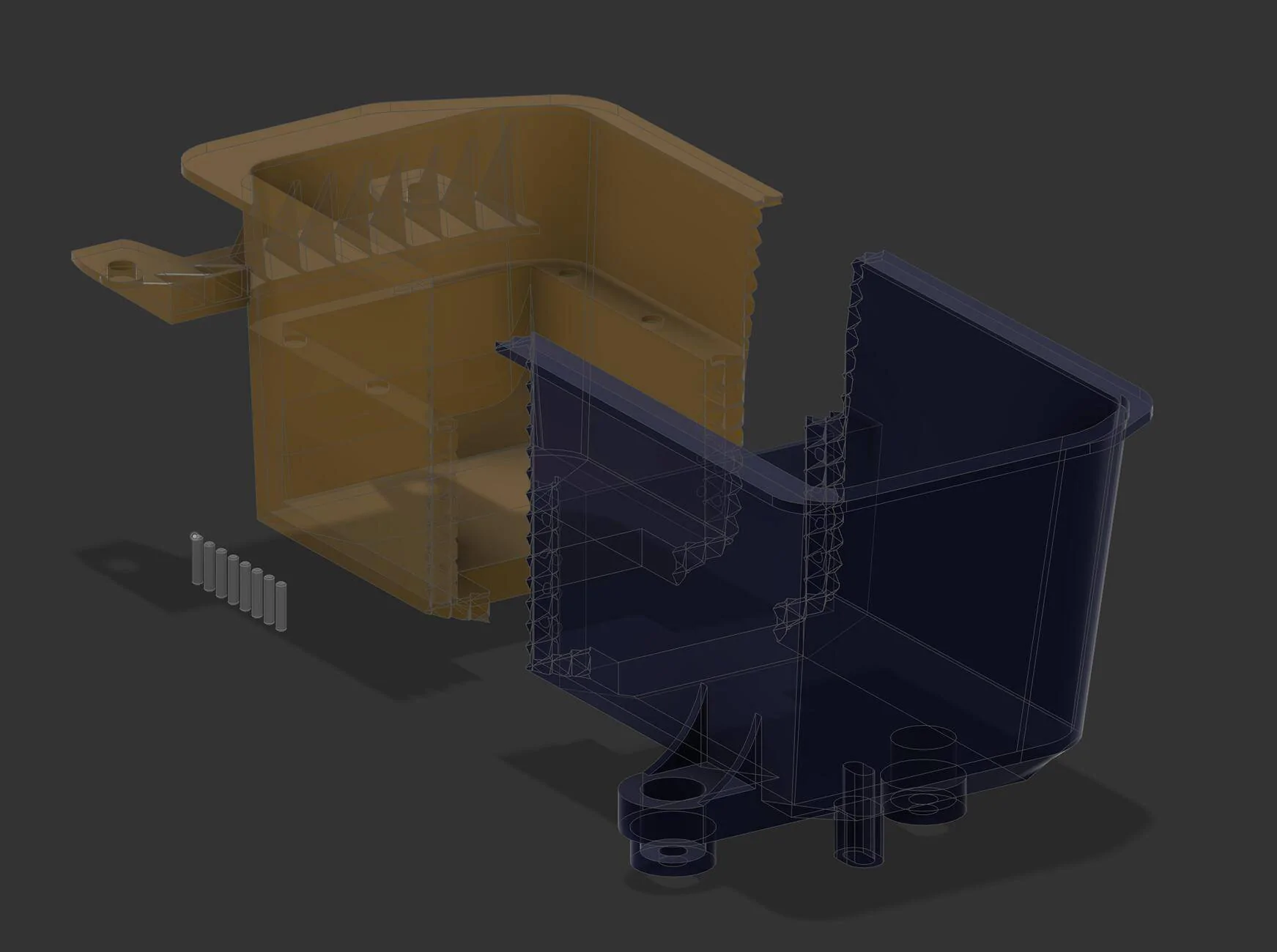

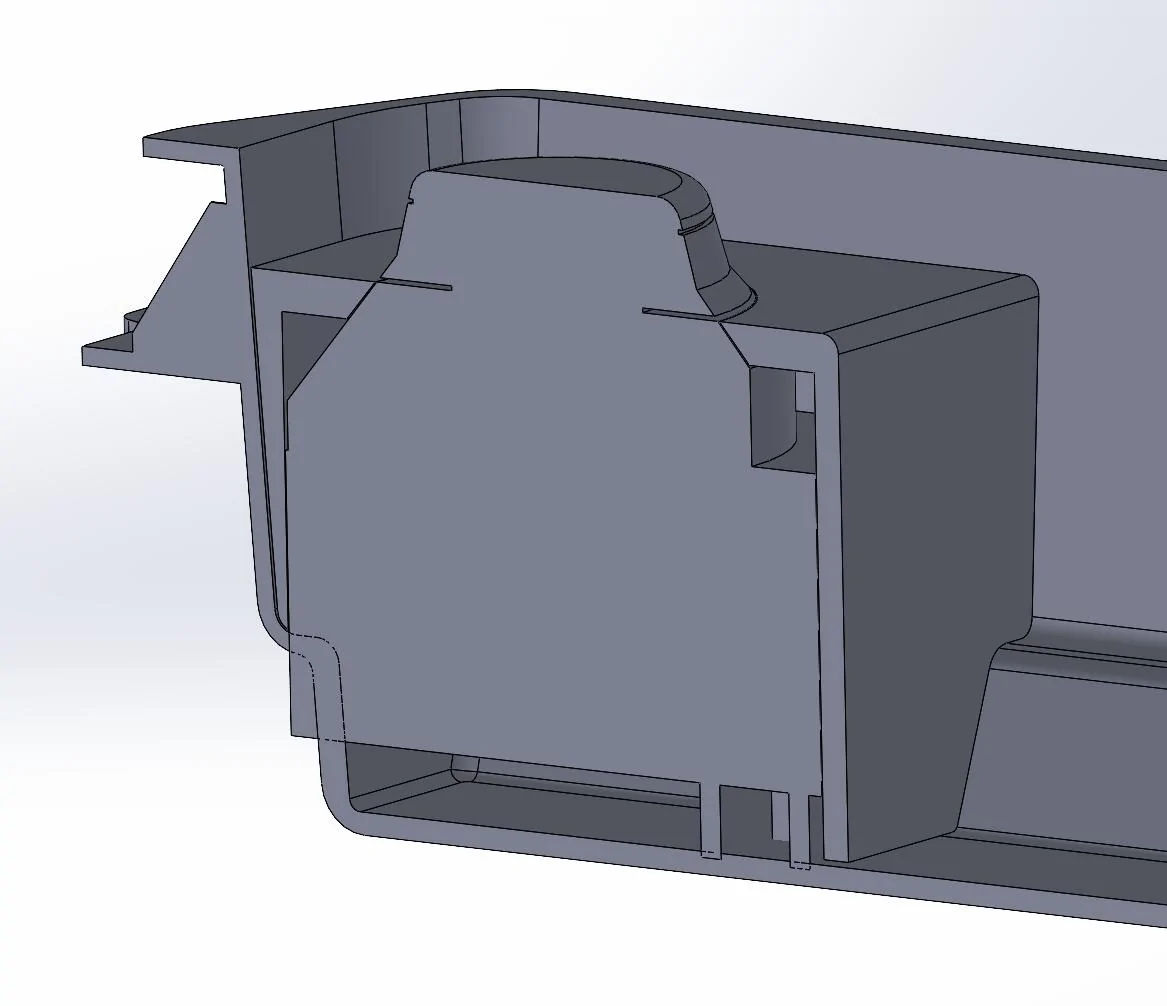

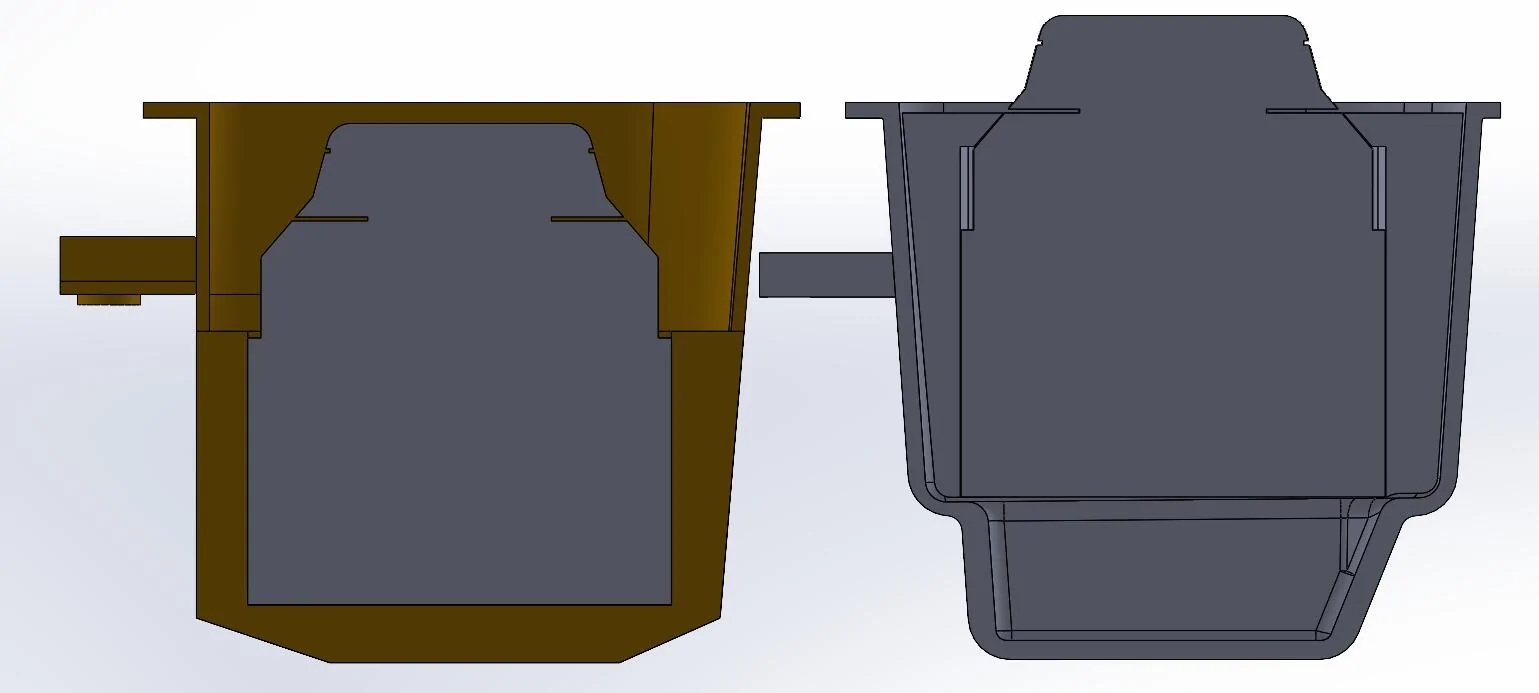

Finally got around to trying the insert in the OEM tub, pardon the draft finish. Plan to print again myself as I had some layer separation and the corners lifted off the bed screwing up the carbon fiber pattern a bit. I also didn't like the position of the z seam, and would recommend locating them towards the center console. Can also do a finer layer height (could probably go down to 0.1mm) to reduce lines on the visible face and eliminate need for any post-processing.

Great press fit on the shifter module with the tabs removed. Fits pretty well in the tub with some minor sanding on the draft faces. I went ahead and tightened the corner radius nearest the driver so it should fit even better than displayed here. The nice thing is it's a blind press into the tub when installed so you can make future modifications without needing to rip the console apart again once the tub itself is installed. It presses in surprisingly well and doesn't move around at all, but for security I suppose you could double sided tape it in place.. Only requisite modification from OEM is the hole for the harness to pass through, and I cut the bottom mat to fit the new length and cover the mounting bolt. Debated cutting the tray cover to fit as well but don't think I could get a clean enough edge against the print face.

Attached are all the models for the insert and the OEM tub (.steps, .stl and .sldprt included for SW for Makers users) if anyone wants to modify further. Unfortunately probably won't work as-is with the foldable work surface, at least not without mutilating the bottom tub. At that point I'd probably recommend just sourcing the complete custom tub from @ENDianDigital. But if somebody wants to try I'm open to help adjust the model accordingly.

Great press fit on the shifter module with the tabs removed. Fits pretty well in the tub with some minor sanding on the draft faces. I went ahead and tightened the corner radius nearest the driver so it should fit even better than displayed here. The nice thing is it's a blind press into the tub when installed so you can make future modifications without needing to rip the console apart again once the tub itself is installed. It presses in surprisingly well and doesn't move around at all, but for security I suppose you could double sided tape it in place.. Only requisite modification from OEM is the hole for the harness to pass through, and I cut the bottom mat to fit the new length and cover the mounting bolt. Debated cutting the tray cover to fit as well but don't think I could get a clean enough edge against the print face.

Attached are all the models for the insert and the OEM tub (.steps, .stl and .sldprt included for SW for Makers users) if anyone wants to modify further. Unfortunately probably won't work as-is with the foldable work surface, at least not without mutilating the bottom tub. At that point I'd probably recommend just sourcing the complete custom tub from @ENDianDigital. But if somebody wants to try I'm open to help adjust the model accordingly.

Attachments

-

1.6 MB Views: 63

ENDianDigital

Active member

Love the clean OEM look! Great alternative for those that want to just use the OEM tub with a completely drop-in shifter option (with absolutely no build volume concerns). I think this definitely warrants a "remake"/fork on Thingiverse if you want to just go that route. Happy to add them to my original project post though if you'd prefer. Great work!Finally got around to trying the insert in the OEM tub, pardon the draft finish. Plan to print again myself as I had some layer separation and the corners lifted off the bed screwing up the carbon fiber pattern a bit. I also didn't like the position of the z seam, and would recommend locating them towards the center console. Can also do a finer layer height (could probably go down to 0.1mm) to reduce lines on the visible face and eliminate need for any post-processing.

Great press fit on the shifter module with the tabs removed. Fits pretty well in the tub with some minor sanding on the draft faces. I went ahead and tightened the corner radius nearest the driver so it should fit even better than displayed here. The nice thing is it's a blind press into the tub when installed so you can make future modifications without needing to rip the console apart again once the tub itself is installed. It presses in surprisingly well and doesn't move around at all, but for security I suppose you could double sided tape it in place.. Only requisite modification from OEM is the hole for the harness to pass through, and I cut the bottom mat to fit the new length and cover the mounting bolt. Debated cutting the tray cover to fit as well but don't think I could get a clean enough edge against the print face.

Attached are all the models for the insert and the OEM tub (.steps, .stl and .sldprt included for SW for Makers users) if anyone wants to modify further. Unfortunately probably won't work as-is with the foldable work surface, at least not without mutilating the bottom tub. At that point I'd probably recommend just sourcing the complete custom tub from @ENDianDigital. But if somebody wants to try I'm open to help adjust the model accordingly.

boggle

Well-known member

Will fork when I have a minute, wanted to reprint mine and resolve some of the print issues and include those lessons learned before sending it out for the masses. I know some people here were interested in something printable with a smaller build envelope so I figured I'd get what I have so far out there now that I was actually able to proof it.Love the clean OEM look! Great alternative for those that want to just use the OEM tub with a completely drop-in shifter option (with absolutely no build volume concerns). I think this definitely warrants a "remake"/fork on Thingiverse if you want to just go that route. Happy to add them to my original project post though if you'd prefer. Great work!

Design took much longer than I thought it would, draft angles were conveniently not similar which made for some trial and error that I got fed up with. Ended up actually scanning it into 3D Zephyr and overlaying the mesh over the model to check for any interference. There may be some minor variation in tolerance from tub to tub but hoping the fit should be pretty universal. Thanks again for sending over those parts and providing the initial inspiration for press-fitting the shifter in place.

ENDianDigital

Active member

Curious to hear how it turned out for you. Success?Attempting to print this now. I'm slowing the printing down so it will take a little while to get everything printed (assuming no print issues).

21st Century Truck

Well-known member

Thanks for this.I was doing some FDRS updates today and I have the rubberized Bronco sport rotary shifter (LX6P-7P155-LE) installed. I checked and there were no DTCs listed with the GSM and it showed green in FDRS. I did a read on the GSM configuration, and it came back with the part number I mentioned earlier.

I decided to attempt a PMI on the GSM since I had FDRS open. I tried it stating I had the original module and then again stating I did not have the original module and both attempts failed. It's not surprising, but figured I would let others know who were curious. I did do a VIN Write operation in FDRS which was successful and tried the PMI both ways again and both failed.

I also went with the Bronco Sport rubberized rotary shifter, after my misadventure with the Mach E shifter.

I'm still planning to gently adapt the knurled blue aluminum shifter crown I bought from 5Spurs.com to fit the Bronco Sport shifter head.

Sponsored

BennyTheBeaver

Well-known member

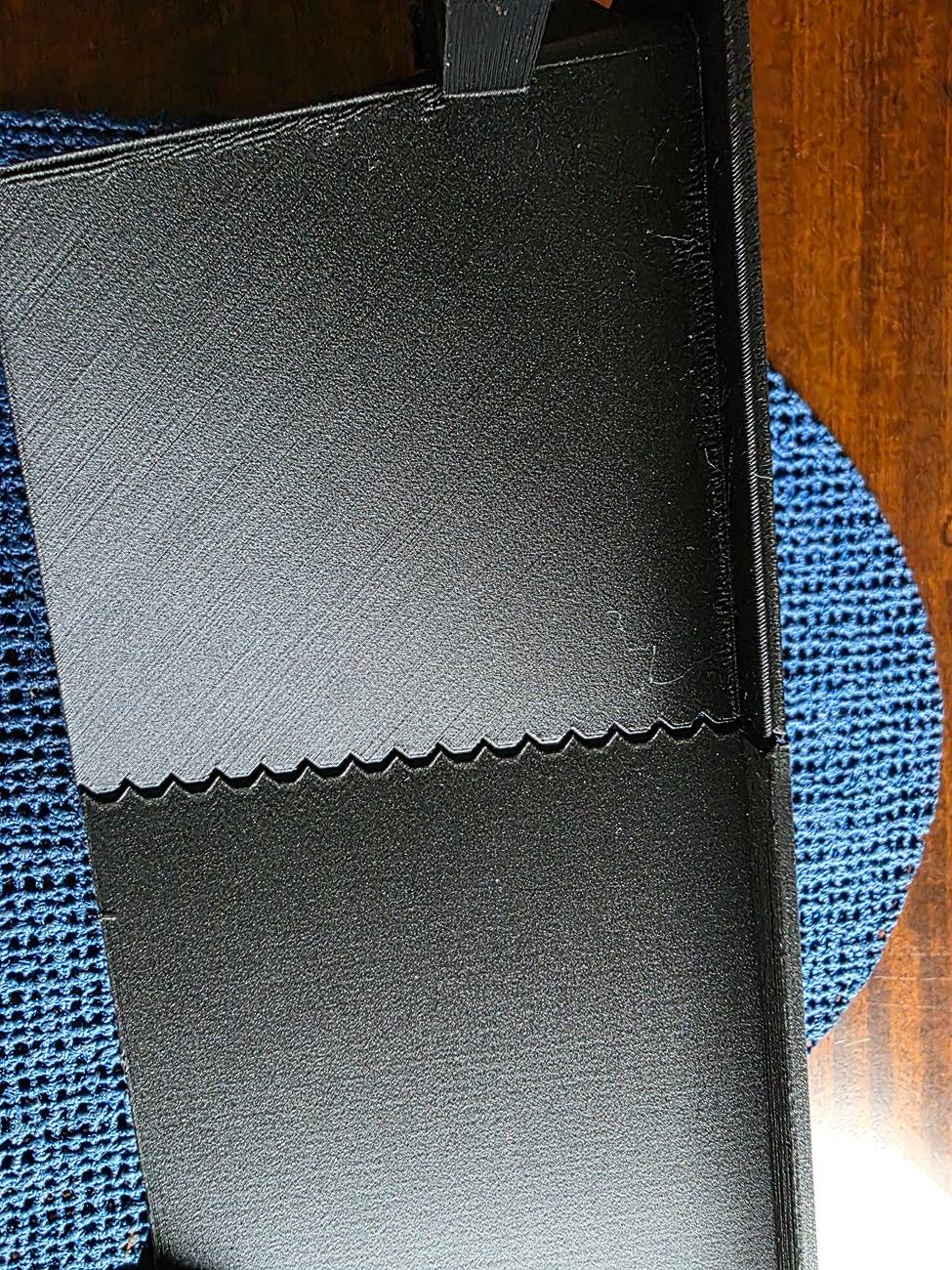

I got everything printed, however I'm unhappy with the way the rear printed, so I'm reprinting that. My initial observations were there was some tiny gaps along the cut (probably due to print accuracy), 3 of the 8 dowels snapped reprinting those as well.Curious to hear how it turned out for you. Success?

BennyTheBeaver

Well-known member

Here are some pictures before I use the JB Weld, sand everything, and paint it (you can see the gaps I was referencing):Curious to hear how it turned out for you. Success?

I think the convoluted cuts is awesome in theory. I don't think the precision and accuracy needed to pull it off makes it a complete solution for everyone as some printers may have issues with that level of precision.

mr.Magoo

Well-known member

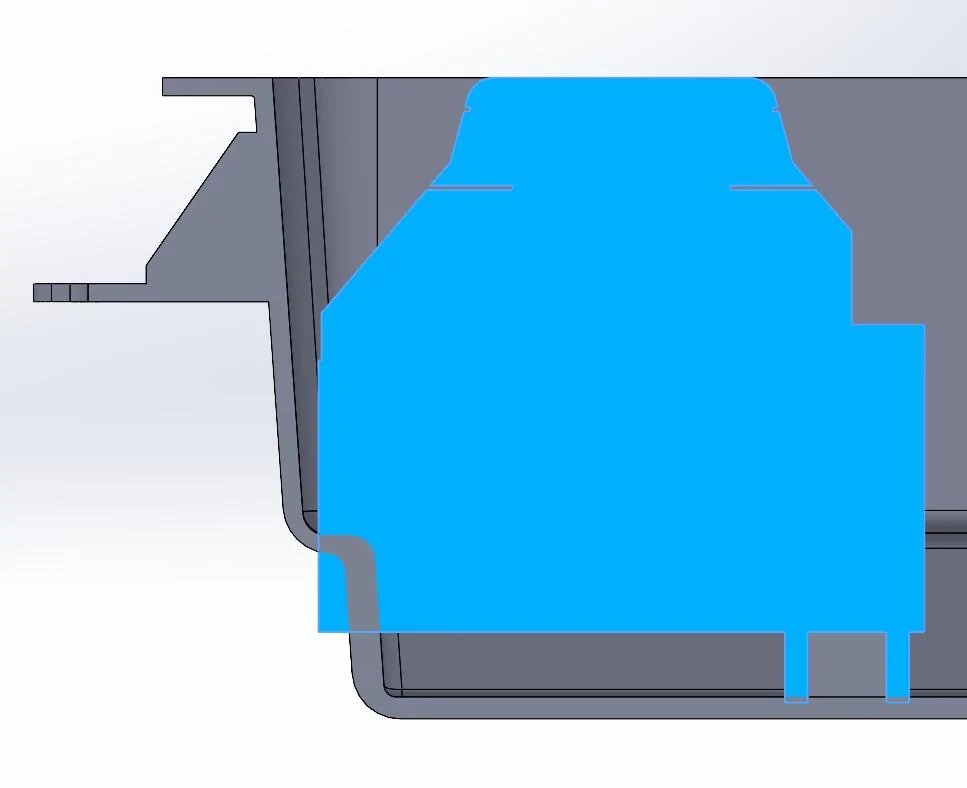

Does the work surface work with this setup? Looks like the shifter sits much higher compared to the full-print versions.Finally got around to trying the insert in the OEM tub

boggle

Well-known member

Not without significant modification to the OEM tub, would basically need to cut out the entire shouldered section below the insert as the shifter is marginally too wide. If shifted it down the requisite 5/8" to be flush with the top of the tub I think the taper towards the bottom would be too narrow to keep a good press fit on the shifter assembly. But here's a model if anyone wants to give it a shot, no promises it will fit.Does the work surface work with this setup? Looks like the shifter sits much higher compared to the full-print versions.

Attachments

-

33.5 KB Views: 38

21st Century Truck

Well-known member

So I learned something surprising (to me) with use of the rotary Bronco Sport shifter in my Lightning.

I often use the interior dash frunk button to open the frunk before I get out, or to open it for someone else while I'm in the cab.

Well, with the rotary shifter I often just plain forget to "park-shift" the truck... and then the frunk dash button doesn't work, of course. And I am mystified for a second or two, and then say "oh..." and I rotary-shift into PARK, and then I try the interior frunk dash button again, feeling sheepish, and of course the frunk opens right up.

I guess I had always shifted into PARK with the OEM push shifter without any thought before hitting the interior frunk button... now I have to retrain my mind and my body haha.

I often use the interior dash frunk button to open the frunk before I get out, or to open it for someone else while I'm in the cab.

Well, with the rotary shifter I often just plain forget to "park-shift" the truck... and then the frunk dash button doesn't work, of course. And I am mystified for a second or two, and then say "oh..." and I rotary-shift into PARK, and then I try the interior frunk dash button again, feeling sheepish, and of course the frunk opens right up.

I guess I had always shifted into PARK with the OEM push shifter without any thought before hitting the interior frunk button... now I have to retrain my mind and my body haha.

Sponsored