Piquette

Well-known member

- First Name

- Trent

- Joined

- Aug 21, 2023

- Threads

- 5

- Messages

- 161

- Reaction score

- 306

- Location

- New Hampshire

- Vehicles

- 2022 Lightning Lariat

- Occupation

- Retired

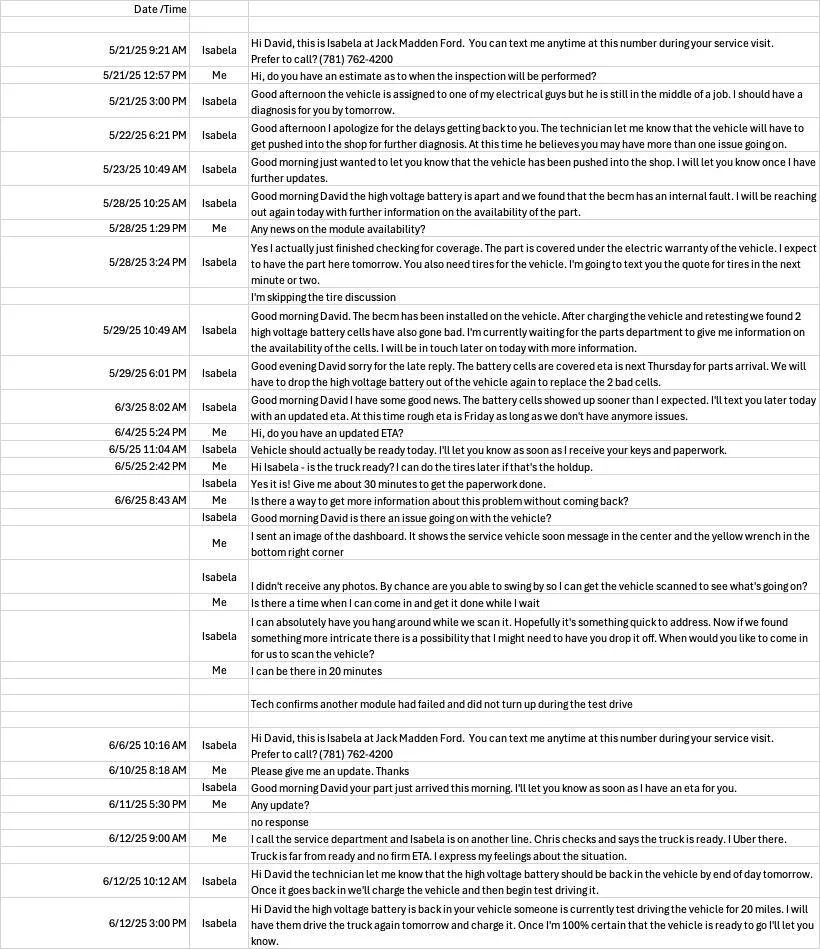

Sounds like they are having to reprogram parts of the charging system to accommodate the new charging port parts. This can sometimes take many hours of a tech’s time.

Sponsored